Overview:

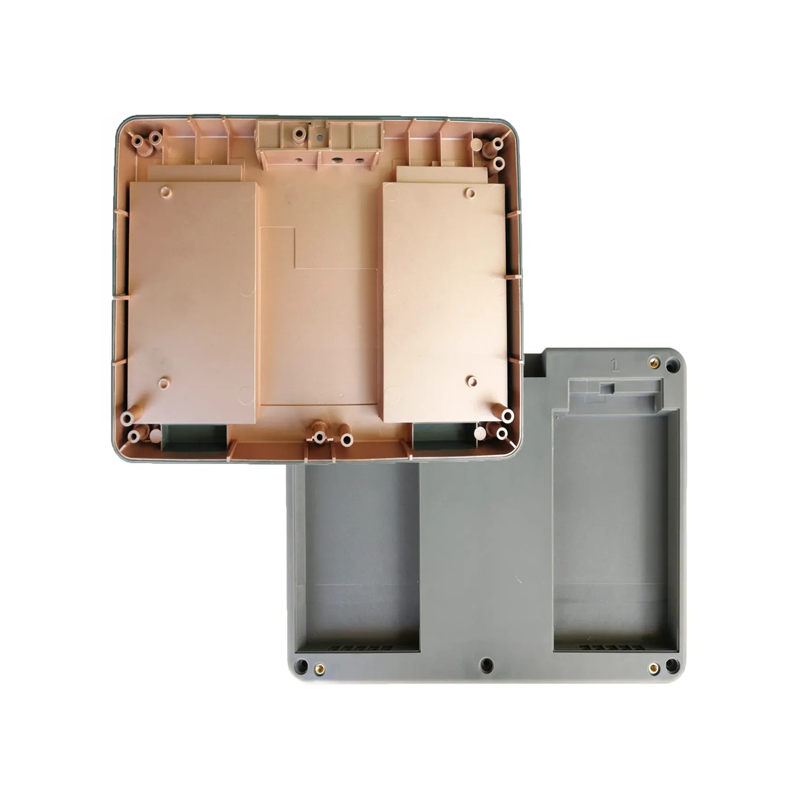

ABS plastic enclosure with TPU overmolding combines a rigid ABS plastic base with a soft TPU overmold, providing durability and an enhanced user grip. This overmolding process offers protection against shock, dust, and moisture while improving product comfort and functionality. At , we offer OEM and one-stop services, specializing in overmolding solutions to deliver high-quality, ergonomic electronic enclosures.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Model Number | OEM |

| Product Materials | PC, PC+ABS, ABS, PP, PVC, POM, TPE, PEEK, TPU, etc. |

| Mould Steel | P20, NAK80, S136, H13, 718H, etc. |

| Mould Lifetime | 50,000 – 1,000,000 shots |

| High Precision | ±0.01mm |

| Certifications | ISO 9001, ISO 14001, IATF 16949 |

| Color Options | Pantone, RAL color code, Actual sample color |

| Size | Custom |

| Technology | Overmolding |

Benefits of Our Products:

- Enhanced Durability and Protection

- Improved Grip and Ergonomics

- Increased Sealing and Waterproofing

- Customization and Aesthetic Appeal

Production Process:

- Design and Prototyping: Custom designs are created using CAD software, followed by prototyping to ensure functionality and performance.

- Material Selection: ABS plastic is chosen for its strength and rigidity, while TPU provides flexibility, durability, and improved grip.

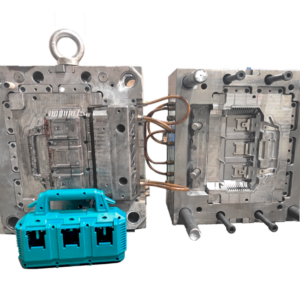

- Injection Molding of ABS Base: ABS plastic is injected into a mold to form the rigid base of the enclosure.

- Mold Preparation for Overmolding: The mold is adjusted to accommodate TPU for the overmolding process.

- TPU Overmolding: TPU is injected over the ABS base to create a seamless, durable bond that adds shock absorption and grip.

- Cooling and Ejection: The part is cooled and ejected from the mold after the TPU overmolding solidifies.

- Quality Control and Post-Processing: The molded parts are inspected for accuracy, trimmed, and tested for defects to ensure they meet precise tolerances.

- Final Assembly and Packaging: The enclosures are assembled with additional components and packaged for shipment.

Our Factory:

We operate a state-of-the-art facility with a full range of advanced equipment to ensure top-tier production quality. Our mold-making capabilities include CNC machines, Mirror EDM, EDM, and Slow-speed Wire Cut WC, complemented by essential auxiliary tools.

Our production lines feature 15 rubber compression machines and 2 LSR injection machines. To uphold stringent quality standards, we rely on 3D projectors, sealing testers, elasticity measurement tools, durometers, and a dedicated QC team.

Additionally, our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measurement tools, high-speed doming machines, die-cutting machines, and CNC machines. This combination of advanced technology, automated production lines, and rigorous quality control ensures the consistent delivery of high-quality products.