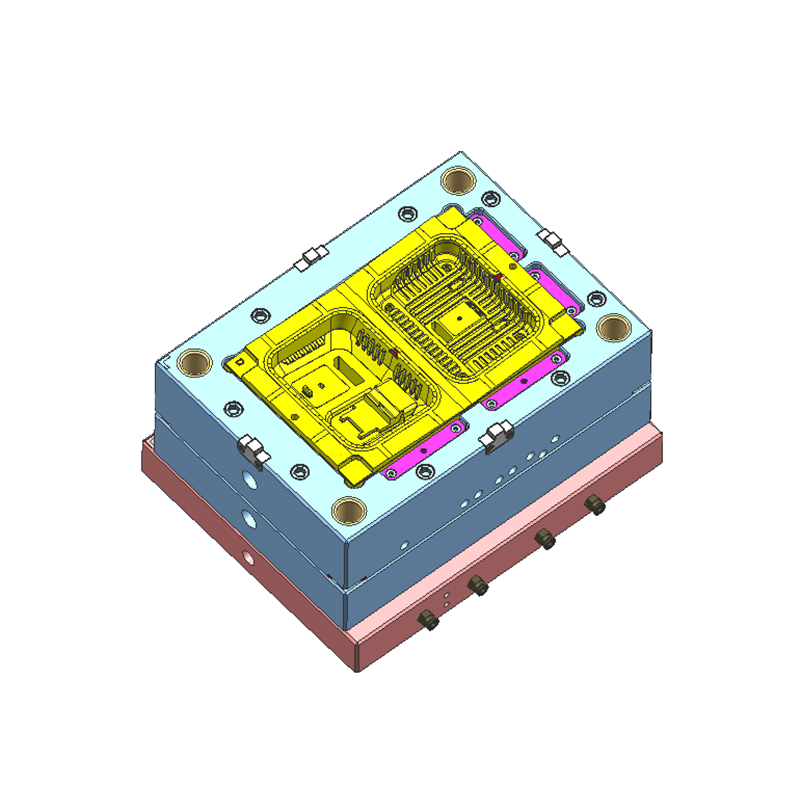

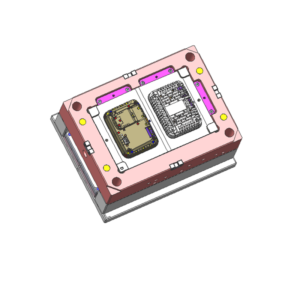

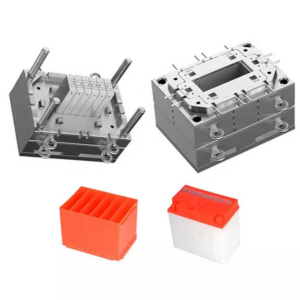

Battery Box Mold Production Plastic Custom Design Battery Case Mould

- Innovative Battery Box Mold Engineering:

Embark on a cutting-edge journey with our avant-garde battery case molds, meticulously designed for the automotive sector. Our revolutionary approach utilizes beryllium copper to ensure not just rapid cycle times but a paradigm shift in cooling efficiency.

- Crafting Excellence with Smart Technology:

Unveil the power of our smart technology integrated into every car battery case mold. Featuring a sophisticated hot runner system and a strategic stripper plate mechanism, we redefine high-speed production, earning accolades for seamless and fully automatic demolding.

- Material Mastery:

Elevate your expectations with our commitment to excellence in material selection. The primary components, ABS and PP, not only define durability but also set the stage for a mold that goes beyond conventional expectations, ensuring the longevity of every molded battery container.

- Global Impact, Local Expertise:

As we showcase an impressive annual production capacity, our global reach echoes our commitment to innovation. With precision plastic molding as our forte, our molds are exported to discerning clients worldwide, leaving an indelible mark.

- Client Applause:

Experience the resounding applause of our satisfied clientele. Our molds not only embody speed and efficiency in cycle times but also resonate with the acclaim of a demolding process that seamlessly combines automation with finesse. It’s not just about manufacturing; it’s about setting a new standard in customer satisfaction.

Controlling Consistent Lattice Size in Battery Case Mold Production

Ensuring uniform lattice size in battery case molds is paramount for flawless production. An excessively loose or tight fit can lead to issues during charging – looseness causes expansion, while tightness obstructs the charging process.

To address this critical concern, our company, backed by over 15 years of invaluable experience, has honed an optimal solution for precise size control. Here’s how we achieve it:

- Precision Through Experience: Recognizing the pivotal role of lattice size, we leverage more than a decade of experience to fine-tune our approach. Our commitment is to strike the perfect balance, avoiding the pitfalls of overly loose or tight dimensions.

- Mold Flow Analysis: Our skilled engineers kick off the process with a meticulous mold flow analysis. This advanced step allows us to comprehensively understand and predict any potential deformation in the battery case during production.

- Strategic Injection Point Selection: Armed with insights from the mold flow analysis, our adept designers strategically choose the injection point positions. This careful selection maintains an optimal injection balance, ensuring that each lattice size adheres to the specified standards.

- Dense Mold Waterway Design: An equally critical aspect is our dense mold waterway design. This design choice is deliberate – aimed at achieving superior cooling efficiency. By facilitating rapid and uniform cooling, we guarantee that each lattice maintains the desired size.