Description:

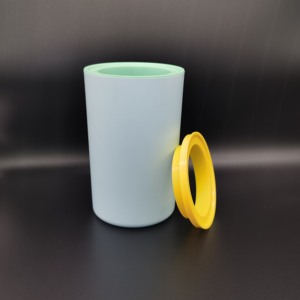

Manufactured with precision using FDA-compliant compression molding, our silicone snack storage bags are designed for durability, flexibility, and food-safe performance. Crafted from medical-grade LSR, they offer outstanding heat resistance (-40°C to 230°C) and eco-friendly qualities. Produced in ISO-certified facilities, these reusable bags are non-toxic and fully customizable in terms of color, size, branding, and functional features such as airtight seals or foldable designs. With certifications including LFGB, RoHS, and REACH, we guarantee top-tier tooling, rapid prototyping, and large-scale production backed by rigorous quality control. Enhance your brand with sustainable, high-performance OEM silicone products.

![]()

Features:

- Capacity: 500ml / 1000ml / 1500ml or Custom

- Use: Ideal for food storage, travel, camping, restaurants, and more

- Material: 100% Food Grade Platinum Silicone

- Place of Origin: Xiamen, China

- Applicable Space: Suitable for kitchen use

- Shape: Customizable design options

- Features: Sustainable, Folding, Stocked, Portable

- Brand Name: OEM

- Logo: Custom Logo Printing Available

- Packaging: OPP Bag or Custom Packaging Options

- Customization: Customizable Logo, Packaging, Color, and Design

Benefits of Our Bag:

- Flash-Free, Precision-Edge Molding

- Uncompromised Food-Grade Material Compliance

- Durable, High-Resolution Logo Embossing

- ISO-Certified Batch-to-Batch Consistency

Quality Assurance:

Our quality assurance protocol ensures uncompromised safety and performance through rigorous material validation, process control, and finished-product testing. Medical-grade silicone compounds are verified via FTIR spectroscopy and GC-MS analysis to confirm FDA, LFGB, and RoHS compliance, ensuring zero heavy metals or harmful volatiles. Compression molding parameters (temperature, pressure, cure time) are monitored in real-time using PLC-controlled hydraulic presses, while post-production inspections include tensile strength testers (ASTM D412), durometer hardness testers, and autoclave sterilization tests for durability. Leak-proof seals undergo burst pressure testing, and dimensional accuracy is validated with CMM (Coordinate Measuring Machines). All processes are executed in ISO 9001:2015-certified facilities, with batch traceability and REACH SVHC compliance. Certifications: FDA 21 CFR 177.2600, LFGB Section 30 & 31, EU 10/2011.

Factory Show:

Our facility is equipped with advanced machinery, including CNC machining, Mirror EDM, EDM, and Slow-Speed Wire Cut (WC), ensuring exceptional precision in mold fabrication. We also operate 15 rubber compression machines and 2 state-of-the-art LSR injection molding machines, maximizing production efficiency. To uphold stringent quality control standards, we utilize cutting-edge instruments such as 3D projectors, sealing testers, durometers, and elasticity measurement devices, all overseen by our certified quality control team. Our operations adhere to ISO 9001 and IATF 16949 certifications, ensuring consistent product excellence. Additionally, automated systems, including AutoDryers, high-speed doming machines, and die-cutting equipment, further enhance production accuracy and efficiency.

![]()