Overview:

Custom Silicone Kitchen Spatulas are versatile, heat-resistant tools made from premium food-grade silicone with reinforced stainless steel cores. Crafted via precision silicone injection molding, they feature a seamless design for easy cleaning and durability. Withstanding temperatures up to 446°F (230°C), they prevent cookware scratches and resist odors and stains. FDA-compliant and non-toxic, they offer ergonomic grips for comfort. Available in custom colors, shapes, and branding, we provide tailored OEM solutions for bulk orders. Elevate your kitchenware with high-performance, branded silicone tools designed for durability and professional customization.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Color | Custom Color |

| Size | Custom |

| Sample | Support |

| Delivery Time | 4-9 days |

| Logo | Custom Logo |

| OEM | Support |

| Technology Process | Silicone Injection Molding |

Advantages of Our Products:

- Crafted from 100% food-grade silicone, rigorously tested by third-party quality assurance for safety and durability.

- Designed for versatile use—microwave, dishwasher, and oven safe up to 450°F (232°C).

- Completely free of BPA, BPS, PVC, lead, and phthalates, ensuring non-toxic and food-safe performance.

- Backed by a 100% lifetime guarantee with proof of purchase, demonstrating our commitment to quality and customer satisfaction.

Production Process:

- Material Selection– High-quality, FDA-compliant food-grade silicone and reinforced stainless steel cores are sourced for durability and safety.

- Precision Molding– Utilizing advanced silicone injection molding technology to ensure seamless, high-precision spatula designs.

- Curing & Finishing– Heat curing enhances strength and flexibility, followed by trimming and surface treatment for a flawless finish.

- Customization & Branding– Custom colors, logos, and designs are integrated through laser engraving or screen printing.

- Quality Inspection– Rigorous testing for heat resistance, flexibility, and food safety compliance, ensuring premium quality.

- Packaging & Delivery– Secure, customized packaging for bulk orders, with efficient logistics ensuring timely delivery.

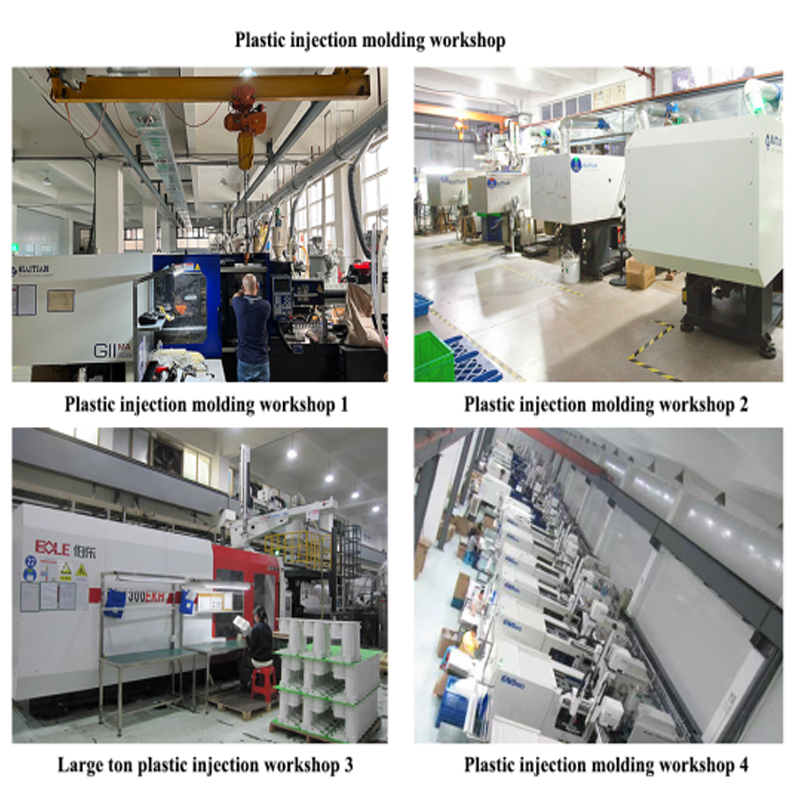

Factory Show:

We operate a fully equipped facility featuring advanced mold-making technology, including CNC machines, Mirror EDM, EDM, and Slow-speed Wire Cut WC. Our production capabilities extend to 15 rubber compression machines and 2 LSR injection machines, with a focus on overmolding expertise. To uphold stringent quality standards, we employ 3D projectors, sealing testers, elasticity measurement tools, durometers, and a dedicated QC team. Our mechanical equipment also includes AutoDryer Lines, automatic screen printing machines, 3D measuring instruments, high-speed doming machines, and CNC machines, all working together to ensure the highest quality production across all stages.