In the manufacturing sector, particularly within plastic injection molding, mold flow analysis stands out as a crucial tool. This analytical method empowers manufacturers to refine injection mold designs and production parameters, ultimately resulting in high-quality plastic components. In this blog post, we will explore what mold flow analysis entails, its benefits, and how it contributes to superior injection mold design.

Understanding Mold Flow Analysis

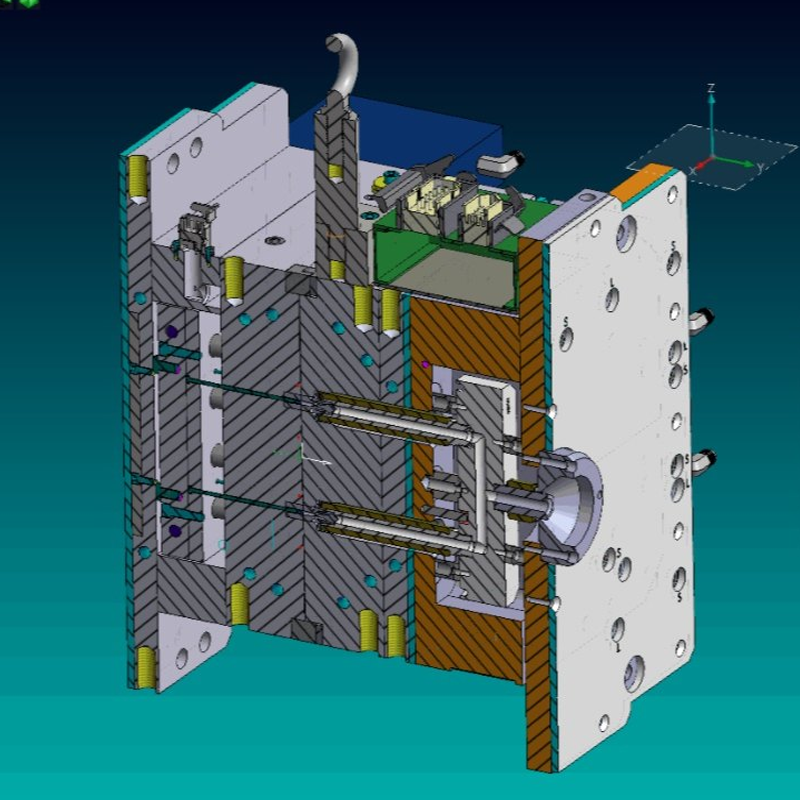

Mold flow analysis is a sophisticated software simulation technique employed in injection molding to forecast and evaluate the behavior of molten plastic as it flows and fills the mold cavity. This process involves creating a virtual representation of the mold cavity and utilizing specialized software to simulate the flow of plastic under various conditions.

During the mold flow analysis, several parameters are inputted into the software, including material properties, injection pressure, temperature, mold geometry, and gate locations. The software then applies mathematical algorithms to predict how the molten plastic will flow, fill the cavity, cool, and solidify into the final product.

The Purpose of Mold Flow Analysis

The primary objective of mold flow analysis is to pinpoint potential manufacturing defects and refine the mold and part designs before production commences. By conducting virtual simulations of the injection molding process, manufacturers can identify issues like air traps, weld lines, sink marks, and short shots early in the design phase. This foresight enables informed decisions that enhance part quality, reduce production costs, and accelerate time-to-market.

How Mold Flow Analysis Functions

Mold flow analysis provides a comprehensive virtual simulation of the entire injection molding process prior to actual production. Here’s an overview of the typical steps involved:

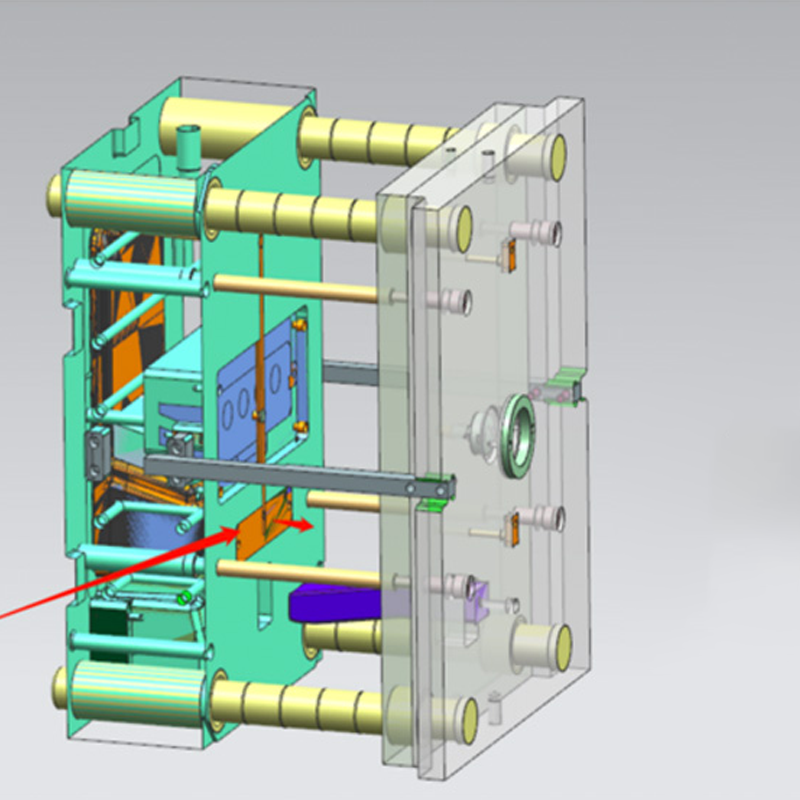

- CAD Model Import: The 3D CAD model of the part design is imported into the mold flow analysis software, which supports various file formats such as STEP and IGES.

- Meshing: The CAD model is divided into smaller finite elements, facilitating numerical calculations during the simulation.

- Material Selection: The specific plastic material for molding is chosen from the software’s extensive database, which includes viscosity, PVT data, and thermal conductivity for numerous materials.

- Simulation Setup: Key process parameters, including melt temperature, injection pressure, gate locations, and cooling channel layouts, are defined.

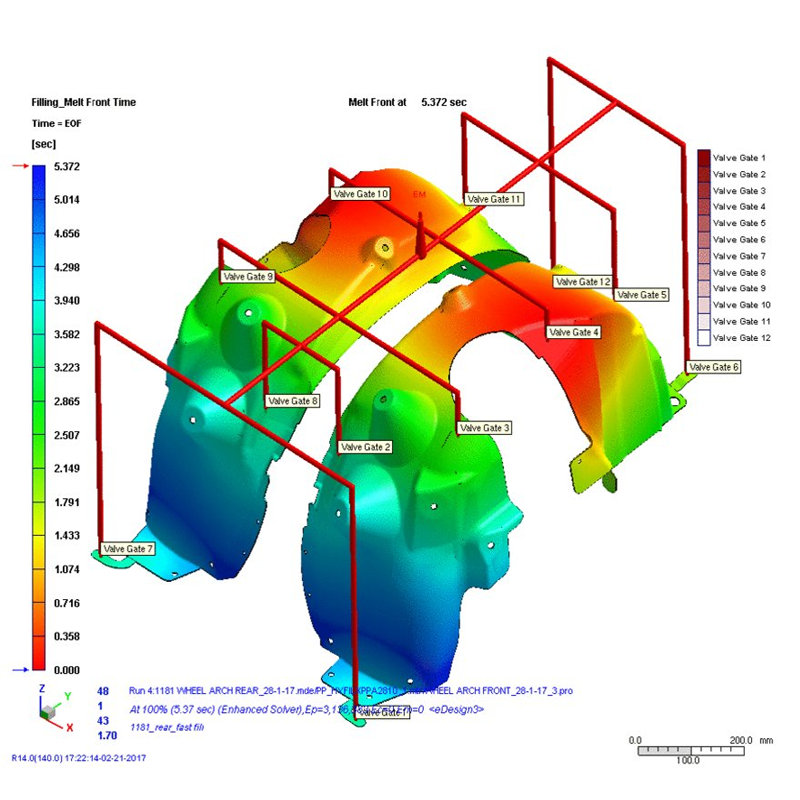

- Filling Analysis: The software simulates how the molten plastic fills the mold cavity, identifying potential defects such as weld lines, air traps, and short shots.

- Pack and Cool Analysis: Following the filling phase, the software simulates the packing and cooling stages, analyzing parameters like pressure distribution and cooling efficiency.

- Result Visualization: The outcomes are visualized through color-coded maps and plots that illustrate fill patterns, temperature distribution, air traps, weld lines, warpage, and more.

- Optimization: The results enable optimization of gate locations, cooling layouts, and process settings to enhance part quality and minimize cycle times.

Advantages of Mold Flow Analysis

Mold flow analysis offers several significant benefits in the injection molding process:

Optimizing Part and Mold Design

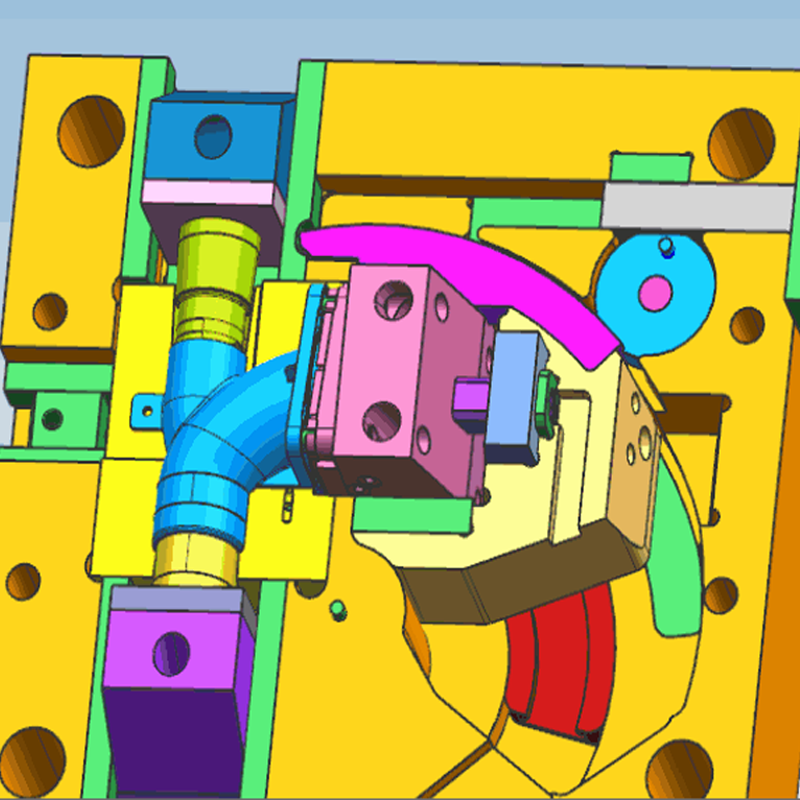

This analysis allows for the virtual testing of various part designs, materials, and processing conditions prior to production, significantly reducing the need for costly iterations and prototypes. It aids in determining optimal gate locations, wall thicknesses, and cooling layouts, ensuring balanced filling and efficient packing.

Enhancing Part Quality and Consistency

By simulating the flow of molten plastic, mold flow analysis predicts filling patterns and potential quality issues, such as short shots, voids, and warpages. It analyzes critical parameters like pressure distribution and temperature variations, ensuring uniform cavity filling and minimizing defects.

Reducing Lead Times and Costs

Mold flow analysis eliminates the need for extensive trial-and-error processes and costly mold reworks by identifying issues upfront. It optimizes cycle times, often reducing them by 10-30%, leading to improved productivity and cost savings.

Evaluating Materials and Processes

The software facilitates testing and comparison of different resin materials and their flow characteristics before production. It also optimizes process parameters like packing pressure, melt temperature, and filling time for efficient molding.

How Mold Flow Analysis Enhances Mold Design

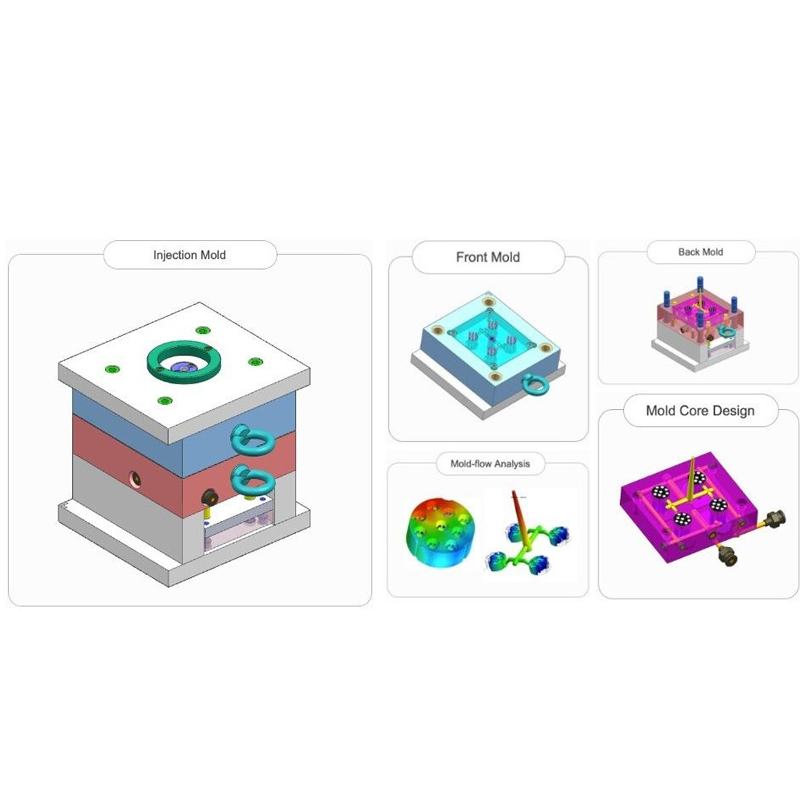

Mold flow analysis significantly contributes to mold design improvement by providing crucial insights and data that optimize various aspects of mold geometry and configuration. Here’s how:

Early Identification of Potential Issues

This analysis allows designers to simulate molten plastic flow within the mold cavity before actual production, helping to identify potential problems such as air traps, weld lines, and sink marks early in the design phase. This proactive approach enables necessary adjustments to mold geometry, ultimately enhancing part quality.

Analyzing and Optimizing Wall Thickness

Mold flow analysis highlights areas with excessive or insufficient wall thicknesses that could lead to defects. By optimizing wall thickness, manufacturers can reduce material usage while ensuring part strength and quality.

Gate Location Optimization

The software simulates molten plastic flow patterns to determine optimal gate locations for balanced filling. Proper gate positioning minimizes defects such as weld lines and uneven shrinkage.

Balancing Flow and Cooling

Mold flow analysis allows designers to predict how plastic will cool and solidify, facilitating the optimization of flow and cooling processes. This leads to uniform part quality, reduced cycle times, and minimized warpage.

Material Selection and Testing

The software enables virtual testing of different plastic materials and their flow characteristics, guiding optimal material selection and processing parameters for effective molding.

Runner and Sprue Design Optimization

Mold flow analysis aids in refining the design of runners and sprues, crucial for ensuring consistent filling during the injection molding process. By optimizing these components, manufacturers can improve part quality and reduce waste.

Validating Design Changes

This analysis serves as a valuable tool for validating design changes before physical implementation. By simulating various design iterations, manufacturers can assess the impact of changes on part quality and filling behavior.

Conclusion

In modern manufacturing, especially in plastic injection molding, mold flow analysis plays a vital role. It enables manufacturers to optimize mold designs, enhance part quality, and streamline production processes with precision. By providing insights into the behavior of molten plastic, mold flow analysis allows for the proactive resolution of potential defects, ensuring high-quality production and reducing costly rework.

For manufacturers aiming to achieve superior results, integrating mold flow analysis into their processes is not just beneficial—it’s essential for success.