Hey,my dear friends,welcome to YJC Polymer! I am thrilled to have the opportunity to discuss with you today the crucial topic of optimizing strategic clearances in mold design. As a leading provider of polymer solutions, we understand the importance of precision and efficiency in mold design to ensure the highest quality of products. In this blog, we will delve into the significance of strategic clearances in mold design and how it can impact the overall product quality. We will also explore the professional techniques and considerations that can be employed to optimize clearances for superior results. If you have any questions or doubts, please feel free to leave a message or reach out to us directly.

Mold design plays a pivotal role in the manufacturing process, particularly in the production of polymer-based products. Strategic clearances within the mold are essential for achieving precise and consistent product dimensions, minimizing defects, and ensuring smooth ejection of the finished parts. By strategically optimizing clearances, manufacturers can significantly enhance the overall quality and performance of their products. This is why understanding the principles and techniques of optimizing clearances is crucial for achieving excellence in mold design.

Flange and Sprue Bushing Design Specifications

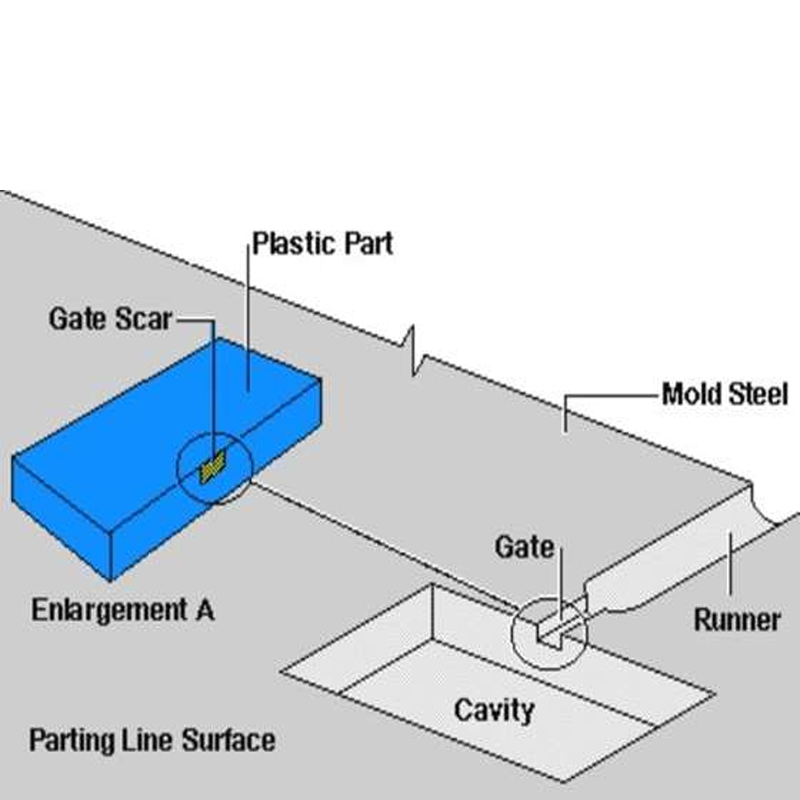

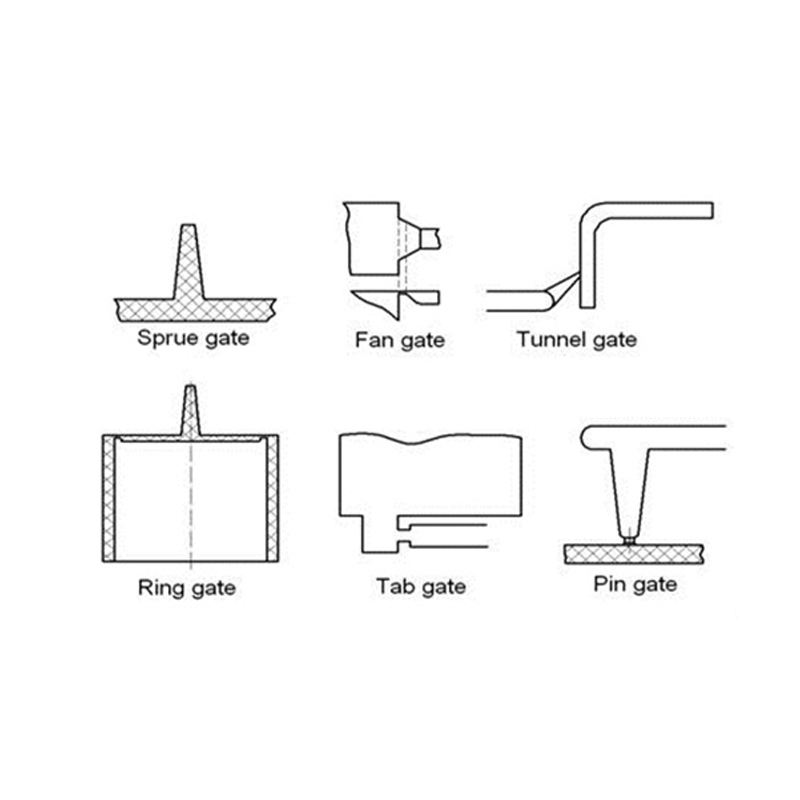

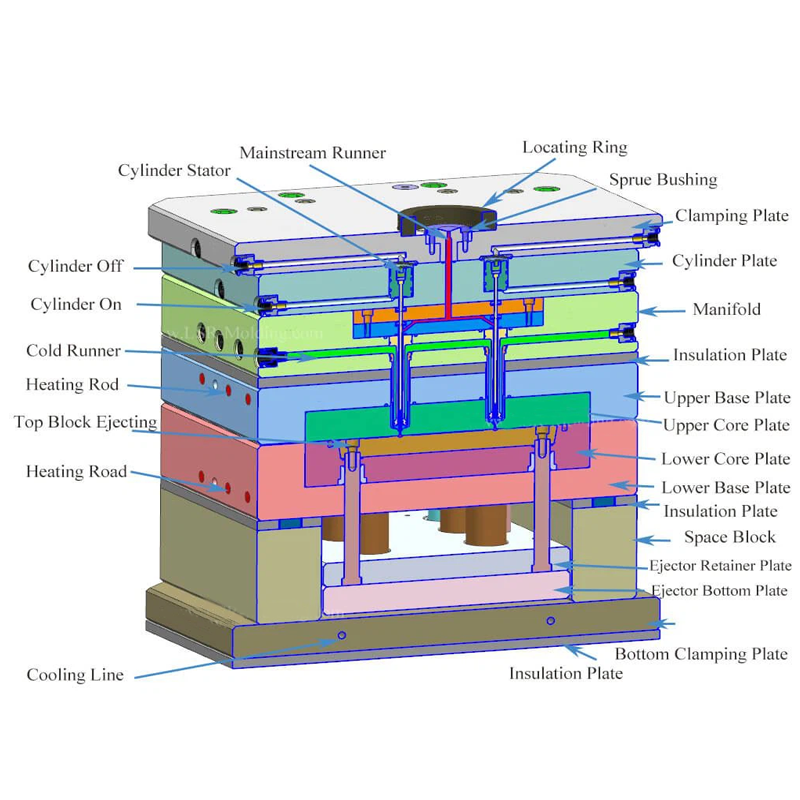

One of the key considerations in optimizing clearances is flange and sprue bushing design specifications. In mold design, the flange must have a unilateral clearance of 0.1 mm from the top clamp plate. The sprue bushing should maintain a unilateral clearance of 0.5 mm from both its mounting plate and the mold base, as depicted in the accompanying diagram. Additionally, a 20 mm clearance is provided around the sprue bushing within the mold cavity to facilitate proper sealing.

Support Pillars and Ejector Components

Furthermore, The second important point is support pillars and ejector components

support pillar, ejector blocks, and spring holes follow these clearance standards: For support pillars with a diameter under 50mm, a unilateral clearance of 2mm is required. For those over 50mm in diameter, a 3mm clearance is needed. Ejector pin through-holes on the B-plate and ejector retainer plate require a unilateral clearance of 0.5mm. The spring holes on the B-plate should have a clearance of 0.5-1mm.

Slider Angle Pins and Slide Locking Blocks Specifications

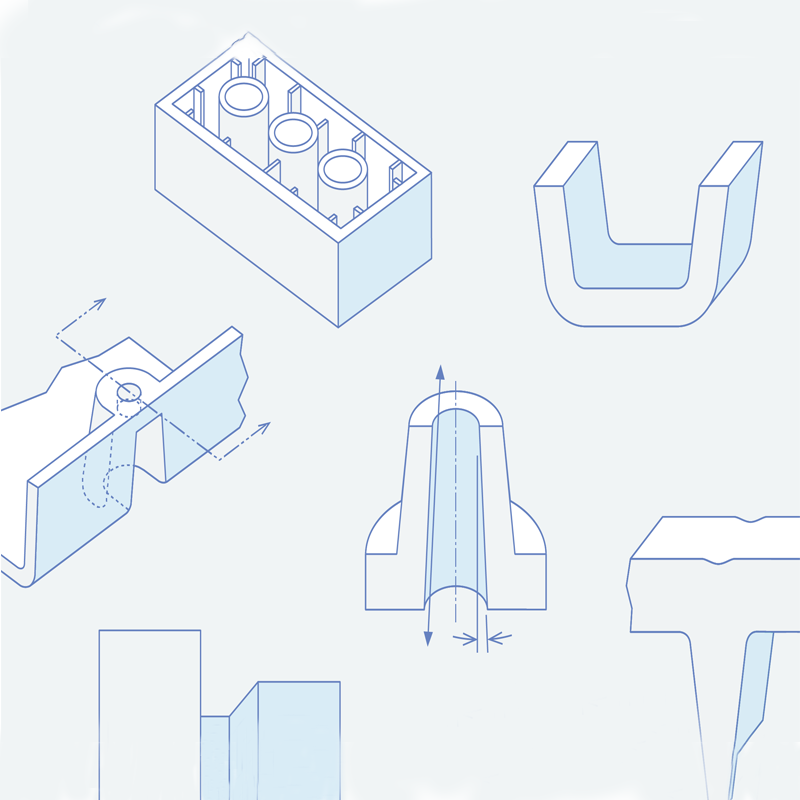

Another factor is slider angle pins, a unilateral clearance of 0.5 mm is required between the pin and its corresponding hole. If the pin extends into the B-plate, a clearance of 2 mm is necessary. The slide locking block should achieve a sliding fit with the B-plate, maintaining a unilateral clearance of 0.5 mm. Limit screws must have a 1 mm clearance on both sides and a 2 mm clearance at the top relative to the slide locking block.

Angled Ejectors and Mold Plates Specifications

On one hand,angled ejectors generally utilize wire-cut round holes or milling techniques to achieve proper clearance with the B-plate. The guide blocks for these ejectors, commonly fabricated from bronze, feature a C-angle with rounded corners to ensure adequate clearance with the B-plate. This design approach supports efficient CNC machining processes.

Mold Plate and Mold Base Clearance Specifications

On the other hand,mold plate screws should maintain a unilateral clearance of 0.5mm from the mold base. This clearance standard also applies to core locking screws relative to the mold core and to small tie-bar sleeves in relation to the mold plate. For inserts, a unilateral clearance of 2mm with rounded corners is recommended to facilitate CNC machining and assembly.

Leveraging CAE Tools for Optimizing Mold Clearances

Another critical aspect of optimizing clearances is the incorporation of advanced simulation and analysis tools in the mold design process. Utilizing computer-aided engineering (CAE) software allows for the virtual testing and optimization of clearances based on the specific material, design, and process parameters. By simulating the mold filling, packing, and cooling stages, manufacturers can gain valuable insights into the behavior of the polymer and identify potential areas for clearance refinement. This proactive approach enables the fine-tuning of clearances before the actual mold fabrication, reducing the likelihood of costly iterations and ensuring an optimized design from the outset.

Material Selection and Surface Treatments

Furthermore, the selection of mold materials and surface treatments can significantly impact the optimization of clearances. Utilizing high-quality, durable mold materials with excellent thermal conductivity and wear resistance is essential for maintaining precise clearances over extended production runs. Additionally, employing advanced surface treatments such as coatings and finishes can reduce friction, adhesion, and wear within the mold, contributing to the preservation of optimized clearances and the overall longevity of the tooling. By prioritizing the selection of superior mold materials and surface treatments, manufacturers can ensure the sustained effectiveness of clearance optimization in mold design.

In Conclusion,optimizing strategic clearances in mold design is essential for achieving high-quality and consistent results in polymer manufacturing. Proper clearance management plays a critical role in ensuring smooth operation, preventing component wear, and facilitating easier machining and assembly. By carefully considering material properties, product design, process parameters, and mold materials, manufacturers can tailor clearances to enhance precision, efficiency, and overall productivity.

Advanced clearance optimization not only improves dimensional accuracy and surface finish but also contributes to cost-effectiveness and the longevity of the tooling. At YJC Polymer, we are dedicated to providing innovative solutions and expertise in mold design to help our clients achieve superior product quality and operational excellence. If you have any questions or need further assistance, please do not hesitate to contact us.assistance in optimizing clearances for your mold designs, please do not hesitate to reach out to us. We are dedicated to supporting your success in the pursuit of excellence in polymer manufacturing.