Top Aluminum Die Casting Injection Mold Manufacturers in China

Overview:

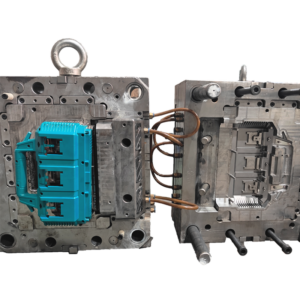

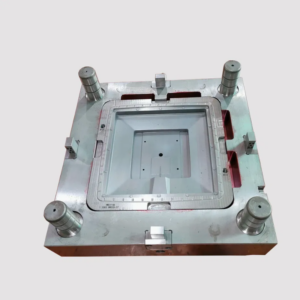

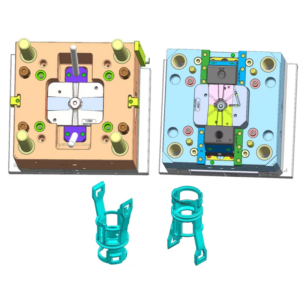

Aluminum die casting injection molds are specialized tools used to form molten aluminum into precise, intricate parts in a high-pressure injection molding process. This method involves pressing molten aluminum into the mold cavity under high pressure, allowing for the creation of parts with excellent dimensional accuracy, intricate detail, and a smooth surface finish. Using aluminum as a material offers benefits such as lightweight, durability and corrosion resistance, making it ideal for a wide range of industrial applications. Advanced machinery and precision engineering ensure consistent quality and efficiency in the production process.

Features:

– Runner Type: Hot Runner / Cold Runner

– Design Software: CAD, ProE, UG, SolidWorks

– Installation Type: Fixed

– Certification: ISO

– Customization: Available

– Transport Packaging: Wooden Case or as per customer request

– Specifications: Tailored to different requirements

– Trademark: Customizable

– Origin: Xiamen, China

– Production Capacity: 50 sets per month

Other Information:

Sample Lead-Time:

– Stock Samples: Available within 1 day from our inventory.

– Custom Samples:Typically ready within 1-2 weeks.

Mass Production Lead-Time:

– Production Timeline:3-7 weeks after receiving the deposit.

Price Terms:

– Terms:EXW, FOB, CFR, CIF Shanghai, or any other airport or seaport in China.

Payment Terms:

– Payment:30% deposit with the balance due upon presentation of the B/L copy.

Die Casting Overview:

Our die casting process utilizes high-pressure injection of molten metal into precision molds, allowing for the production of intricate, dimensionally precise parts with excellent surface finishes and tight tolerances. By employing specialized dies and advanced machinery, we guarantee consistent quality and efficient manufacturing.

Our Advantages:

Production Expertise

– Specialized OEM Services: We specialize in metal stamping, machining, deep drawing, and sheet metal forming, offering a diverse array of finishing capabilities.

Strategic Location

– Xiamen Hub: Situated strategically in Xiamen, bolstering our global service capabilities.![]()

Logistical Efficiency

– Proximity to Ports: Located near Xiamen ports, ensuring streamlined transportation efficiency and cost-effectiveness.

Equipment Overview:

– STATE OF THE ART TECHNOLOGY: Our facility is equipped with world-class machining and quality control equipment, including AgieCharmilles, Mitsubishi, Rhodes, MAKINO, Serein Croma-C and GOM ATOM.

– Medical Grade Facility: We have a Class 100K clean room for high quality medical molding production to ensure top quality for competitive bids and orders.

We welcome you to visit us! At this particular time, we can offer a virtual tour of our factory during working hours in China to show you everything you are interested in.

![]()

![]()