Recent advancements in additive manufacturing have introduced a groundbreaking technology for 3D printing silicone parts. This innovation has garnered significant interest within the 3D printing industry, as traditional methods couldn’t melt and layer silicone like polymers or metals. This development, especially impactful in medical and biomaterial fields, is enhancing existing patient treatments. The continued progress in 3D printing technology is opening up new and previously unimaginable possibilities.

Silicone 3D printing is poised to make a substantial impact on the industry, marking a key milestone in 3D technology evolution. According to Precision Business Insight, the silicone 3D printing market was valued at $1,590.3 million in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 19.9% through 2028. This growth is further fueled by companies developing new silicone-compatible solutions.

Silicone, or polysiloxane, is an inorganic polymer derived from the polymerization of siloxanes, molecules composed of silicon and oxygen atoms. This polymerization happens through a condensation reaction, typically catalyzed by an acid or base, facilitating the formation of bonds between siloxane functional groups. The resulting polymer chains exhibit remarkable mobility due to the silicon-oxygen bonds, giving silicone its notable chemical resistance and physical properties.

Silicone exists in various forms, including oils and rubbers (used as lubricants or hydraulic fluids), gels (used in breast prostheses or bicycle saddles), and elastomers, the most common form used today.

The pioneering company in silicone 3D printing was ACEO, a division of Wacker Chemie AG, which introduced a process similar to inkjet printing in 2016. This method involved applying silicone droplets layer by layer and curing them with UV light. Although ACEO ceased operations in 2021, its early techniques for 3D printing silicone remain in demand across various sectors, including industrial goods, chemicals, and medicine.

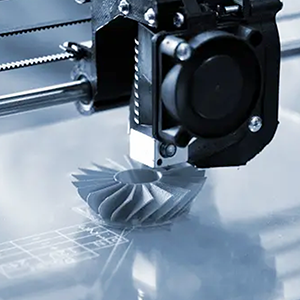

Photopolymerization is one 3D printing technology compatible with silicones, but extrusion technology also works. In extrusion-based methods, silicone is packaged in connectable syringes with plungers. Volumetric metering pumps ensure precise material dispensing, with the silicone applied through a precision nozzle. This process is akin to FFF/FDM extrusion technology, but the silicone fluid maintains a specific viscosity to layer properly. The material hardens through a crosslinking reaction during and after printing, acquiring its final properties.

Silicone 3D printing offers several advantages. It allows for the creation of flexible and durable 3D models that can withstand high loads and pressures. Silicone’s resistance to extreme temperature and radiation fluctuations makes it less susceptible to damage compared to materials like glass. Its transparency is beneficial for visually inspectable models. Additionally, silicone’s conductive, insulating, and biocompatible properties make it suitable for various 3D printing applications.

However, there are limitations. Accessibility in terms of hardware and materials is still a challenge, with few manufacturers offering compatible machines, leading to high costs and limited material options. Current 3D printers for silicone also have low print volumes, limiting mass production. Many devices use a single print head, producing simple models without support structures, although dual-head IDEX solutions are becoming more available. Post-processing requires longer curing times, extending production timelines.

Silicone 3D printing is ideal for small to medium batch production, prototyping, and creating unique shapes. The medical sector benefits greatly, using silicone 3D printing for custom implants, prostheses, and medical models that mimic human tissue. Soft robotics and flexible electronics also leverage silicone’s properties for producing delicate, flexible components. Consumer goods, particularly in clothing and wearable prototypes, are other areas of application.

Key players in this market include Elkem Silicones and various 3D printer manufacturers like Deltatower, innovatiQ, Lynxter, Spectroplast, and San Draw. For more information on silicone 3D printers, further research and related articles are recommended.

Our 3D printing service offers custom parts printed on demand. Our skilled team includes mechanical and CNC engineers, prototype craftsmen, and surface treatment specialists. Our cutting-edge facility features SLA 3D printers, CNC machining centers, and specialized equipment for UV curing, spray painting, and silk screen printing. Contact us today to bring your custom parts to life.