Silicone molding for medical components is a versatile field, classified by material type, part size, production volume, and molding technology. This article focuses on the specifics of silicone molding, highlighting the differences between High Consistency Rubber (HCR) and Liquid Silicone Rubber (LSR).

High Consistency Rubber (HCR)

High Consistency Rubber (HCR) has a peanut butter-like consistency. It uses either a platinum or peroxide catalyst, mixed with the base on a two-roll mill. HCR can be shaped through compression molding or transfer molding. In compression molding, the material is placed between two plates that compress and heat it, causing excess material to escape along the parting line. This traditional method is cost-effective for low-volume production. Transfer molding, on the other hand, involves transferring the material through a runner, sprue, and gate system into the mold cavity. This method is ideal for silicone parts requiring specific properties or for low to mid-range production volumes.

Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber (LSR) uses liquid injection molding (LIM) technology. LSR has a corn syrup-like consistency, is supplied in drums, and uses a platinum catalyst. LIM includes various subcategories such as overmolding, two-shot molding, and micromolding.

Overmolding: This process involves molding silicone over a substrate like a thermoplastic part, titanium part, or silicone tube. An operator or robot places the initial component into the mold, and silicone is molded onto it, creating a single, combined part. This method requires precise operator training to avoid misplacement and potential tool damage.

Two-shot silicone-thermoplastic molding: This process combines silicone and thermoplastic materials simultaneously. The thermoplastic component is molded in one part of the mold, while silicone is overmolded in the other. The silicone-overmolded parts are removed when the mold opens, and the thermoplastic parts are transferred to the silicone side. This technique demands specialized equipment, high-temperature thermoplastic, self-bonding LSR, and a deep understanding of material properties and thermodynamics.

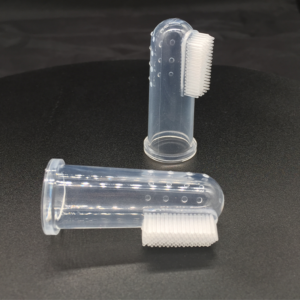

Micromolding: As medical devices become smaller, micromolding of LSR is increasingly popular. Using high-precision tools, appropriate presses, and robotics, tiny silicone parts with a mass as low as 0.01g can be produced. Examples include integrated seals, soft tips for surgical tools, and micro-valves.

Methods of Silicone Molding

Silicone Compression Molding

![]()

![]()

This labor-intensive process involves pre-catalyzed silicone rubber. Pigments are added by mixing on a two-roll mill, which is prone to contamination. The material is then weighed and shaped to fit the mold cavity, compressed between heated plates to melt and cure the silicone. Although simple and cost-effective, this method has higher contamination risks and labor intensity.

Liquid Silicone Injection Molding (LIM)

LIM involves mechanically mixing a two-component LSR compound and injecting it into a mold. This closed-loop system keeps the raw silicone and pigments sealed, reducing contamination risk. The material and pigment are injected into a water-cooled barrel to prevent premature catalysis, then into a hot mold for rapid curing. LIM is ideal for high-volume production due to its fast curing rate and minimized handling, which reduces contamination.

We have mature technology and sophisticated equipment for silicone materials. For more information on molding types or the specific capabilities of yjcpolymer, please contact us today.