Overview

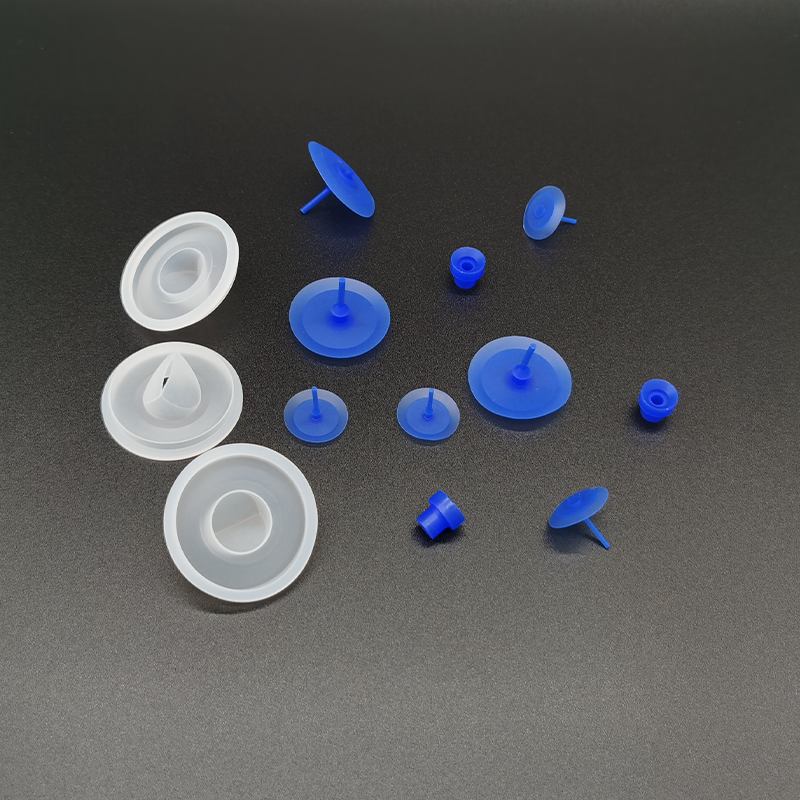

The Silicone Rubber Duckbill Check Valve is designed for precise flow control in various applications, including food-grade environments. This valve, also known as a one-way or check valve, ensures efficient and reliable performance by allowing fluid to flow in one direction while preventing backflow.

The Silicone Rubber Duckbill Check Valve is fabricated from high-quality silicone rubber, providing excellent elasticity and durability. This valve is suitable for both low and high-pressure systems, making it versatile for controlling or limiting the flow of air or liquids. It is produced using either compression mold tooling or liquid silicone rubber (LSR) injection molding, allowing for the creation of various shapes and sizes as per customer requirements.

Key Features

- Position Independent: Operates effectively in any orientation, ensuring versatile application.

- Low Opening Pressure: Allows immediate and free flow of fluids with minimal pressure.

- Non-Tortuous Flow Path: Ensures a direct and smooth flow of liquids or gases.

- High Flow Rate: Delivers a high flow rate relative to its compact size.

- Minimal Internal Volume: Virtually eliminates internal volume and dead space, reducing the risk of contamination.

- Particle Compliance: Designed to handle particles without clogging or degradation.

- Corrosion Resistant: Made from materials that resist corrosion, enhancing durability.

- Wear Resistant: High resistance to wear ensures a long operational life.

- Cost-Effective: Offers an economical solution without compromising on performance.

Manufacturing Capabilities

- Mold-Making Expertise: With in-house precision mold-making technology since 2008, we offer a one-stop service for producing silicone rubber compression molded components, plastic injection molded parts, and liquid silicone rubber molding components.

- Material Knowledge: Extensive understanding of elastomeric materials and their properties, ensuring optimal performance in fluid control applications.

- Production Experience: Proven track record in avoiding deformation and damage from production to shipment through careful material selection, design improvements, and proper packaging.

- Rapid Prototyping: Capability to quickly produce prototypes with full-sized production equipment and materials.

- Clean Room Manufacturing: Experienced in maintaining clean room standards to ensure high-quality precision manufacturing.

Applications

The Silicone Rubber Duckbill Check Valve is ideal for use in:

- Food and Beverage Industry: Ensures hygienic flow control in food-grade applications.

- Medical Devices: Provides reliable flow regulation in medical equipment.

- Industrial Systems: Suitable for various industrial applications requiring precise flow control.

- Consumer Products: Used in household appliances and consumer goods for effective fluid management.

Our factory specializes in producing high-quality silicone air and liquid control valves, leveraging advanced technology and extensive experience to meet diverse customer needs. We invite you to contact us with your design specifications, samples, or ideas to create the perfect silicone rubber valve for your application.