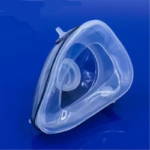

Manual Resuscitator Mask

1.Materials: Silicone/LSR/PVC etc.

2.Sizes/Types: Neonate, Infant, Pediatric, Adult etc.

3.Materials Hardness: 15 Shore A -90 Shore A

4.Disposable Mask: PVC; Reusable Mask: Silicone/LSR.

5.Working Temperature: LSR: -20°C – 450°C; Silicone: -40°C- 230°C; PVC -10°C- 85°C

| Product | Cat. No. | Specification | Description |

| Anesthesia Mask | 5401100 | Neonate(0#) | 15mmOD, Non-inflatable |

| Anesthesia Mask | 5401110 | Infant (1#) | 15mmOD, inflatable |

| Anesthesia Mask | 5401120 | Child (2#) | 22mmID, inflatable |

| Anesthesia Mask | 5401130 | Small Adult (3#) | 22mmID, inflatable |

| Anesthesia Mask | 5401140 | Medium Aduit (4#) | 22mmID, inflatable |

| Anesthesia Mask | 5401150 | Large Adult (5#) | 22mmID, inflatable |

Equipments & Advantage:

1. Five workshops: Mold-Making, Silicone Rubber Compressive, Plastic Injection, LSR Injection, and Assembly workshop.

2. Mold-Making Equipment: CNC, Mirror EDM, EDM, Slowspeed Wire Cut M/C and other auxiliary equipment etc.

3. Production Equipment: 15 Sets Rubber Compressive Machines, 8 Sets Haitian Plastic Injection Machines, 2 Sets LSR Injection Machines.

4. Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Dustfree Environment: LSR injection Machines, 3 Sets Rubber Compressive Machines, and Assembly Line in 100,000 rating Dust-free Plants.

6. Senior engineers will provide you with technical support and solutions.

7. Quote and provide samples quickly according to 2D/3D drawings or samples.

8. ISO9001 international quality system certification, professional QC personnel control the quality of products, to ensure that the factory 100% qualified

9. The products are manufactured in the country of origin and customized for all kinds of medical and food grade silicone products, with market competitiveness.