Material:ABS, PC/ABS, PP, PC, POM(Acetal/Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), PMMA(Acrylic), SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE(Teflon), GPPS, PPS, PPO, PES, CA, etc.

Performance: UV Resistance, Heat Resistance, Fire Resistance, Good Flexibility, High Impact Resistant, etc.

Certificate: IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A

Drawing Format: .stp / .step / .igs /.stl /.dwg / .pdf. etc.

Color: Almost all PMS colors available.

Function: Industrial parts /daily supply / Medical grade supply, etc.

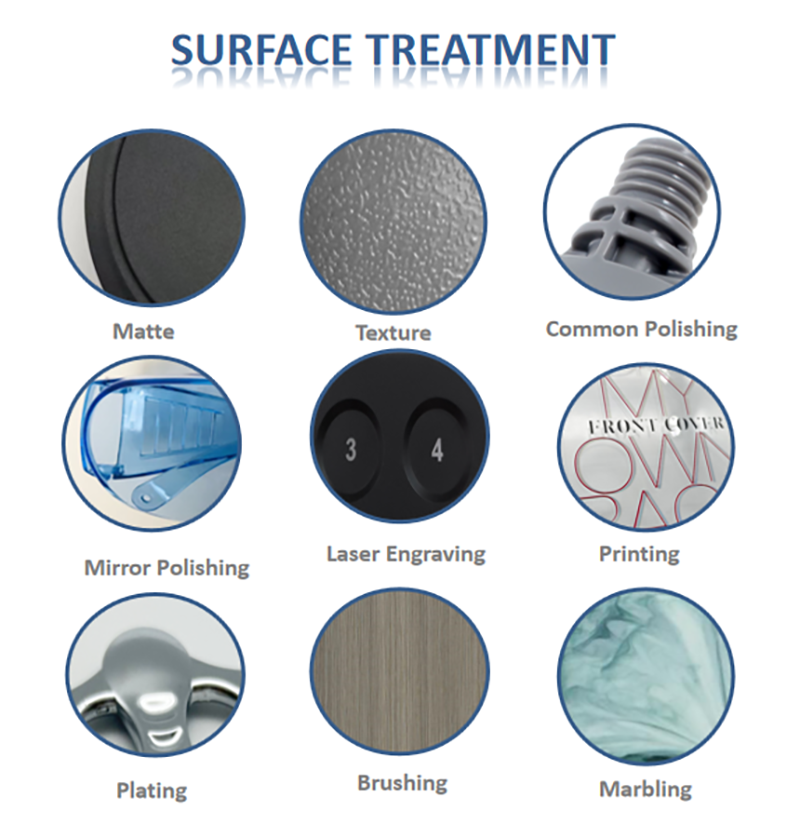

Surface Treatment: Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc.

Mold Material: S136H, 718H, NAK80, P20, H13, etc.

Sample: Available. One cavity sample mold or 3D printing.