One-stop Solution for Custom Toolings for Plastic Electronics Housings and Enclosures

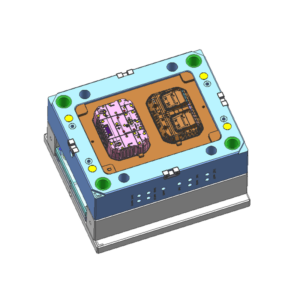

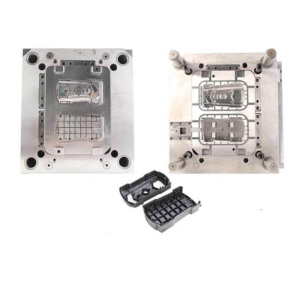

We custom produce plastic injection molds and parts for plastic electronics housings and enclosures, such as plastic loud speaker mold, plastic switch box mold, plastic camera housing mold, plastic phone case mold, plastic power bank mold, plastic door bell mold, plastic wire harness mold, plastic terminal block mold, plastic earphone plug mold, plastic meter box mold, etc. We do both tooling and parts mass production. Welcome to have your own molds and parts custom made.

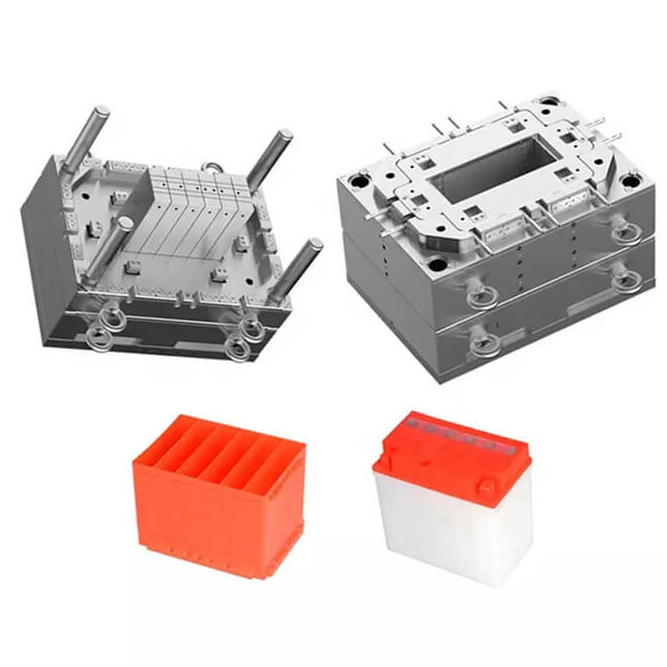

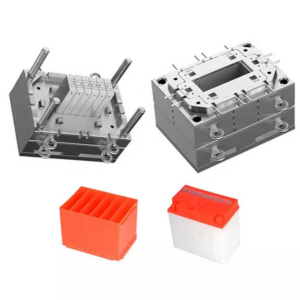

We strive to ensure our plastic battery box moulds and battery case moulds are of the highest quality by utilizing the most advanced technologies in mould design and implementation.

What We Do?

- Mold Building (common molds, hot runner molds, metal-to-plastic over molding / insert molding)

- Parts Production

- Logo Printing (Pad printing, Silk Screen Printing, Ultrasonic Welding, Painting, Plating, etc.)

- Assembling (as per your detailed requirements)

- Packing and Shipping

Complementary Services

- Design and Engineering

- 3D Printing

- Large-Scale 3D Metal Printing

- CNC Machiningy

- Fabrication and Welding

- Assembly and Finishing

- Inspection and Testing

- One-stop service

- DFM Moldflow

Mould Material:NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc

Mould Cavity:Single or Multi, as per your requirements

Gate Type:Sprue gate, Pin-point gate, Submarine gate, etc

Design Software / Program:UG, PROE, Solidworks, etc.

Surface Treatment:Polished (Glossy or common), Matte, Textured

Mould Life:10,000-1,000,000 shots

We have advanced software-aided of CAD, CAE, CAM, CAQ to implement design, CNC machine ,engraving machine,EDM,Grinding machine,drilling machine to processing, quality control; experienced technical team, superb technology, advanced manufacturing equipment to promise and support our services.